Building and restoring classic wooden sail, row and power boats with the finest boat building materials and craftsmanship. | ||

By Thad Danielson | ||

|

The boats I like and have always liked on the water are integrated structures of wood and mechanical fasteners. Just as trees vary in their look and habits, woods with different characteristics find differing uses in boat construction. Likewise, different waters and people have developed widely varied types of vessels. Because the boats must float, they require attention to the details of every part. With this attention to detail and the desire for smooth motion through the water, boats have been among the most

beautiful human constructions everywhere in the world. Deciding on the right boat for you involves a large numbers of factors both practical and aesthetic. A boat's operation in the water will test her structure. Since over heavy structure will detract from a boat's performance, we seek a balance between use, weight and strength. The constantly varying stresses in a seaway produce flex in the boat's shape. Boat builders over the last ten thousand years have developed boat structures which use the unique characteristics of wood to advantage. These characteristics arise from wood's primary purpose; evenly distributing the force of wind from the trees outer leaves and branches, to the roots in the ground. What works great for trees works equally well for your boat. Wood bends in beautiful fair curves, and flexes and returns to shape as strains are distributed throughout the structure.

Whether your boat is lapstrake or caravel, 12 feet long or 30 feet long, wood has long proven ideal for building boats. Wood naturally takes the fair forms that make a boat functional and beautiful. The complex structural engineering behind the shape is itself beautiful in the classic wooden boat. Wood is uniquely resilient, insulating, dampening and workable. Different species of wood exhibit different characteristics. Heavy, strong White Oak is used for primary structure such as keels. We use light and resilient Cedar for planks and decks. There are woods like teak and locust that excel in rot resistance and have other properties which make them useful in boats. All the scores of woods used in boats are beautiful in their own right and great variety is possible on inboard joinery as in all elements of wooden boats. All wood comes with grain and other qualities developed in the life of the tree before the mill cuts the wood. Along with wood's finest qualities for the boat builder come problems. When cutting a tree into logs and logs into planks and boards, the cutter tries to cut to best use the tree's wood; you never know what the wood is like until it is cut. While qualities like strength and rot resistance are predictable from species to species; differences occur from tree to tree and in different tree parts from roots to branches. Picking lumber and then using it to the best advantage of the wood and the boat under construction makes building wooden boats endlessly fascinating. Hull Types

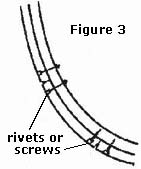

Lapstrake construction can be light because it is a fully integrated structure. For caravel (fig 3) or smooth skin construction the scantlings must be considerably heavier. Whether fit tight wood to wood or caulked with cotton or oakum in a beveled seam (fig 4), caravel planks are fit to swell when wet, compress the joints, and create a watertight hull.

Building a boat begins with the choice of design or type. With the design in hand we need to choose and find materials for the required parts. Different designs require different setups. We need the space to build. We need the dry strong stock for the molded structural elements, and fresh sawn green stock for steam bending. We need lofting space and mold stock if we are building a boat that requires lofting and molds. Plans in hand and lofting done, the backbone parts are made, fastened together, and set up with whatever molds are required for the hull we are building. Every boat and builder is different. The same boat can be built many different ways. The thing is to get out all the parts, fastening each in its place until the whole structure and fabric of a boat is caulked and finished to satisfaction. Then comes launching and cruising.

12' Norwegian Pram

|

For small lightweight boats, I like the lapstrake structure developed in Scandinavia over a thousand years ago. With the edges of lightweight planks beveled and riveted together, the hull itself is an integrated structure. With copper rivets securing the plank joints (fig 1) this structure will be watertight yet flexible. With sawn or steam bent transverse reinforcement installed, called timbers (or frames or ribs) (fig 2), and additional longitudinal members to reinforce rails, support seats, thwarts, decks and

cabins, the lapstrake hull becomes a powerful yet lightweight vessel. Because the hull planking forms a structural entity the supporting structures need not be heavy in a lapstrake boat.

For small lightweight boats, I like the lapstrake structure developed in Scandinavia over a thousand years ago. With the edges of lightweight planks beveled and riveted together, the hull itself is an integrated structure. With copper rivets securing the plank joints (fig 1) this structure will be watertight yet flexible. With sawn or steam bent transverse reinforcement installed, called timbers (or frames or ribs) (fig 2), and additional longitudinal members to reinforce rails, support seats, thwarts, decks and

cabins, the lapstrake hull becomes a powerful yet lightweight vessel. Because the hull planking forms a structural entity the supporting structures need not be heavy in a lapstrake boat. "Scantlings" is a boatbuilder's term for the cross sectional dimensions of a boat's structural parts. With heavier scantlings, stronger fastenings, and closer spacing of parts such as timbers and fastenings, a hull with the same shape could be made more powerful though also heavier. Boat designers and builders work with the fastener schedules and scantlings developed over the last few thousand years and must take the

intended use of the vessel into account when planning new construction.

"Scantlings" is a boatbuilder's term for the cross sectional dimensions of a boat's structural parts. With heavier scantlings, stronger fastenings, and closer spacing of parts such as timbers and fastenings, a hull with the same shape could be made more powerful though also heavier. Boat designers and builders work with the fastener schedules and scantlings developed over the last few thousand years and must take the

intended use of the vessel into account when planning new construction. With a boat's rounded shape this compression is only possible if the planks are fastened to an inside structure with enough strength to hold them in line and fair. In compression, the plank skin of a caravel hull spreads the loads of crashing waves directly through the fasteners to the underlying timbers. The fastening schedules and timber structure must be strong enough to hold the planks against their own

compression forces and against the wracking forces of the seaway. These wracking forces include the loads

centered on mast, oar locks, and engines, as well as wave action and grounding.

With a boat's rounded shape this compression is only possible if the planks are fastened to an inside structure with enough strength to hold them in line and fair. In compression, the plank skin of a caravel hull spreads the loads of crashing waves directly through the fasteners to the underlying timbers. The fastening schedules and timber structure must be strong enough to hold the planks against their own

compression forces and against the wracking forces of the seaway. These wracking forces include the loads

centered on mast, oar locks, and engines, as well as wave action and grounding.